Vietnam is one of the most wonderland of tropical fruit. The taste of variety of fruits, sometimes sweet, sometimes sour, but always healthy natural goodness. Vietnamese fruits that are loved not only by local people but also by foreign tourists that have been to Vietnam and share their ideas about this tasty tropical fruits. All fruits can be easily found in supermarkets, street markets and grocery stores all around Vietnam. There are also many street vendors who push carts to sell the fruit in the corners of almost any streets. Especially in the southern part of the country where you can try many different types of fruits of different colors and flavors all year round.

There is various method of food preservation, in this topic, we will talking about dried fruit. Drying is one of the oldest methods of food preservation. It is still used widely to preserve foods for home consumption and for sale. Dried fruits are one of the most popular products made by small-scale processors.

Dried Fruit – general information:

Drying removes the water from foods so that the growth of micro-organisms is inhibited. It also reduces the weight and bulk of foods which cuts down on transport and storage costs.

Sun drying is the simplest and cheapest method of drying. It is used for high volume foods such as grain, rice, sultanas and raisins. The disadvantage of sun drying is that the processor has very little control over the drying conditions and the quality of the dried fruit.

There are two main forms of dried fruit- semi-moist and dried fruits:

- Semi-moist fruits, such as grapes contain naturally high levels of sugar which means they can be preserved with a higher moisture content than most other dried fruits. Semi-moist fruits can have a moisture content as high as 25% and are consumed as they are without re-hydration. The sugar content of other fruits can be increased by soaking the fruits in sugar solution prior to drying. These fruits are known as osmotically dried fruits.

- To make higher quality products, processors use an artificial dryer. There are several types of dryer available (solar, diesel, electric, biomass powered) according to the different needs of the user.

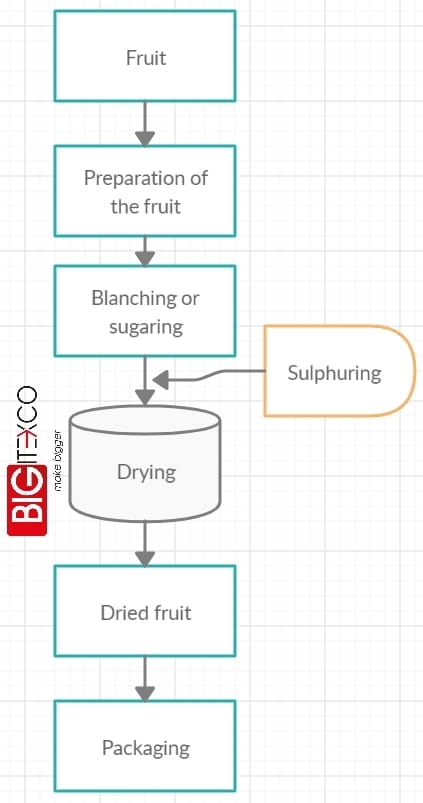

Processing details for dried fruit production

- Preparation of the fruit

- All fruit to be dried should be handpicked and not shaken from the tree. To obtain maximum yields of top-quality dried product, all fruit should be ripe and free from bruising. Any rotten or bruised fruit should be thrown away. For maximum profitability, the dryer should be loaded to maximum capacity as often as possible, therefore it is advisable to buy more fruit than is required.

- Bananas have a low level of acidity and turn brown very rapidly after peeling and cutting. To prevent this, they should be immersed in water containing sodium metabisulphite (400 parts per million of sulphur dioxide) immediately after peeling. Unpeeled fruits should be washed in a mild disinfectant solution made from one part of bleach to 50 parts of water.

- Care must be taken not to break the skin of the fruits as this will contaminate the flesh. Gloves and aprons must be worn to protect the workers hands and clothes. Ten litres of treated water will be sufficient for about 20kg fruit.

- The wash water should be changed after this amount has been washed as it becomes contaminated by the fruit. Soft fruit, such as berries and apricots, are delicate and should be handled carefully to avoid bruising.

- Washed fruits are carefully peeled to remove all the peel and any damaged parts of the flesh. Fruits are cut into slices of varying thickness depending on the type of fruit and the dryer. The following points are useful to consider thick pieces dry at a slower rate than thinner ones; very thin pieces tend to stick to the drying trays and may be difficult to remove; thicker pieces may not dry fully in the center and will not store well; packets of mixed thick and thin pieces do not look attractive.

Only stainless steel knives should be used to peel and chop the fruit. Other metals will discolour the fruit flesh.

- Blanching or sugaring

- This stage is optional, but some processors choose to soak fruits in a sugar syrup prior to drying. There are several benefits of including this process. There are also constraints to sugaring.

- Fruit pieces are immersed in a concentrated sugar solution for up to 18 hours. They are rinsed in clean water to remove any excess syrup before drying.

- Most vegetables and some fruits are blanched before drying to inhibit enzyme activity and to help preserve the color. The material is cut into appropriate sized pieces and plunged into boiling water for up to 5 minutes. They should be blanched in small batches to ensure that each piece is properly heated through. If too many pieces are put into the water at one time, the water temperature will drop and prolong the blanching time. After blanching for the required time, vegetables are rapidly cooled by plunging into cold (or iced) water.

- Sulfuring (optional)

- Sulphuring or sulphiting is an optional stage of processing. The main benefit of sulphuring is to preserve the fruit color. Some consumers object to chemical preservatives and prefer naturally dried fruits.

- Sulphur dioxide gas (SO2) is applied to the fruit pieces by placing them in a cabinet or tent in which sulphur is burned. The gas is absorbed by the fruit. For most fruits, 5-6g sulphur per kg food is adequate. The gas given off is toxic and corrosive. Therefore, sulphuring should be carried out in a well ventilated place, using appropriate equipment. See the information on sulphuring for more details. Sulphite can be included in the sugar syrup (as sodium or potassium metabisulphite).

- Drying

- Fruit pieces are arranged on mesh-bottom trays so that they are not touching or overlapping. The fruit should be loaded into the trays as soon as it is cut. This prevents the pieces from sticking together and allows the drying process to start as soon as possible.

- The trays should be brushed clean to remove any old fruit pieces.

- The trays should be loaded into the dryer as soon as they are ready. The dryer doors should be closed after each tray is loaded.

- Direct sunlight should be avoided as this bleaches the color and reduces the level of vitamins A and C. The drying temperature should be controlled to avoid over-heating and spoilage of the fruit. Most fruits are dried at about 60-70 deg C.

- Fruits are dried until they have the desired final moisture content (15% for conventionally dried fruits; 20-25% for osmotically dried (sugar-treated fruits).

- Packaging

- Dried fruits should be packaged immediately after drying to prevent them absorbing moisture from the surrounding air. After drying, fruits can be packed in bulk in sealed moisture-proof polyethylene bags then packed into smaller packets at a later date.

Practical aspects of food drying

To produce good quality dried fruit and vegetables that are acceptable for both export and local consumption, there are several factors to consider.

- These include the following:

- Purchase of good quality fresh produce

- Careful transport and storage

- Proficient preparation of produce

- Correct loading and operation of the dryer

- Drying to the correct final moisture content

- Proper packaging and storage of the dried product

- Achieving good product quality

- Efficient management of all operations to assure quality, minimize losses and maximize business profitability.

- All activities must be carried out with due diligence at all times with regard to cleanliness, hygiene and food safety aspects

Sugaring fruit for drying

There are various methods of applying sugar to fruits. The simplest is to dust with a fine layer just before drying. This gives the fruit a sweet coating and may help to slow down browning. Fruit pieces can be dipped in a concentrated sugar solution, made by dissolving sugar (sucrose) in water. While the fruit is immersed in the syrup, water is drawn out of the fruit by a process of osmosis (the principles of osmosis are that water diffuses through a semipermeable membrane from a weak to a stronger solution until both solutions are the same strength. The sugar also diffuses through the membrane, but at a much slower rate than the water.)

When the fruit is immersed in a concentrated sugar solution, water equivalent to over 50% of the initial fruit weight can be removed, which reduces the amount of water that has to be removed during the drying phase. The increased sugar concentration in the fruit acts as an extra preservative which means that the fruit can be dried to a higher moisture content (25%).

Advantages of sugaring

During osmosis, the material is not subjected to a high temperature over an extended time which minimises heat damage to the colour and flavour. A high concentration of sugar surrounding the material prevents discolouration by enzymic or oxidative browning. The fruits can have a good colour without the need for chemical treatment such as sulphuring. As water is removed by osmosis, some of the fruit acid is removed along with it. Combined with the uptake of a small amount of sugar, this produces a blander and sweeter product.

Disadvantages of sugaring

Sometimes a thin layer of sugar is left on the fruit after drying, which may be undesirable. It can be removed by rinsing the fruits after soaking and before drying. The process produces a dilute syrup as a by-product.

The syrup can be brought back to full strength by concentrating or adding more sugar. However, there is a limit to the number of times it can be re-used. To be more cost effective, the syrup could be used to make fruit nectar. Including this step adds unnecessary complications to the drying process.

Sugar may be an expensive commodity which makes the option financially unattractive to small-scale processors.